How are guitar strings made? It’s a question that many guitarists have, but few know the answer to. In this article, we’ll take a look at the process of making guitar strings, from start to finish.

Editor’s Note:Understanding how guitar strings are made is important for several reasons. First, choosing the right strings can significantly impact your playing experience and sound quality. Second, learning about a guitar string’s components can help you maintain, restring, and repair your instrument properly.

To make guitar strings, manufacturers start with a long, thin wire. The wire is usually made of steel, but other materials like nylon, aluminum, and nickel can also be used. The wire is then wound around a core, which is typically made of a material like nylon or steel. The core provides the string with strength and stability.

Once the wire is wound around the core, the string is coated with a thin layer of material like nickel or silver. This coating protects the string from corrosion and wear and gives it a smooth, consistent finish.

The final step in making guitar strings is to stretch them. Stretching the strings helps to set the intonation and ensure that they are in tune. After the strings are stretched, they are cut to length and packaged for sale.

There are many different types of guitar strings available on the market, each with unique characteristics. The type of string you choose will depend on your playing style, the sound you want to achieve, and the type of guitar you have.

Key Differences:

| Nylon Strings | Steel Strings | |

|---|---|---|

| Material | Nylon | Steel |

| Sound | Warm, mellow | Bright, clear |

| Tension | Lower tension | Higher tension |

| Price | Less expensive | More expensive |

Now that you know how guitar strings are made, you can make more informed decisions about the strings you use. Consider factors like the sound you want to achieve, the type of guitar you have, and the tension of the strings. With so many different types of strings available, you’re sure to find the perfect set for your needs.

1. Materials

The choice of materials used in guitar strings significantly impacts their sound, feel, and durability. Understanding the properties of each material is crucial for selecting the right strings for your playing style and instrument.

- Steel: Steel strings are the most common type and offer a bright, clear sound with excellent sustain. They are also relatively inexpensive and durable.

- Nylon: Nylon strings produce a warm, mellow sound and are often used on classical and flamenco guitars. They are less durable than steel strings but have lower tension, making them easier on the fingers.

- Aluminum: Aluminum strings are a newer type of string that offers a unique blend of brightness and warmth. They are also very durable and resistant to corrosion.

- Nickel: Nickel strings are similar to steel strings but have a slightly warmer sound. They are also more resistant to corrosion than steel strings.

The type of material used for the core of the string also affects its sound and feel. Nylon cores are common for classical and flamenco guitars, while steel cores are more common for electric and acoustic guitars. The core material can also impact the string’s tension and durability.

By understanding the different materials used in guitar strings, you can make informed choices about the strings you use, allowing you to optimize your playing experience and achieve the desired sound.

2. Core

Understanding the core of a guitar string is crucial in exploring how guitar strings are made. The core provides the foundation for the string’s strength, stability, and overall performance.

- Material: The core material, typically nylon or steel, significantly impacts the string’s sound and feel. Nylon cores offer a warm, mellow tone and lower tension, making them suitable for classical and flamenco guitars. Steel cores produce a brighter, more resonant sound and are commonly used in electric and acoustic guitars.

- Strength and Stability: The core provides the backbone of the string, ensuring it can withstand the tension and vibrations produced during playing. A strong and stable core allows for precise intonation and tuning stability.

- Durability: The core material also influences the string’s durability. Nylon cores are less durable than steel cores and may be more susceptible to breakage, especially under high tension. Steel cores, on the other hand, offer greater durability and can withstand higher tension levels.

- Sound Projection: The core material can affect the string’s sound projection and sustain. Nylon cores tend to produce a warmer, less projecting sound, while steel cores provide brighter, more resonant tones with longer sustain.

By understanding the role and characteristics of the core, guitarists can make informed decisions when choosing strings that best suit their playing style, instrument, and desired sound.

3. Winding

The winding process is a crucial step in the manufacturing of guitar strings, directly influencing their tension and tone. By carefully controlling the winding tension, manufacturers can achieve specific tonal characteristics and playing feel.

- Tension: The tension of the winding determines the string’s overall tension, which affects its pitch, intonation, and playability. Higher tension strings produce a brighter, more resonant sound, while lower tension strings have a warmer, mellower tone.

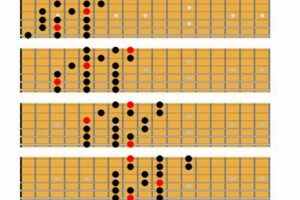

- Tone: The winding pattern and tension can also impact the string’s harmonics and overtones, contributing to its unique tonal character. Different winding techniques, such as roundwound or flatwound, create distinct sonic profiles.

- Feel: The winding process influences the string’s feel and response under the fingers. Roundwound strings have a rougher texture that provides more grip and articulation, while flatwound strings feel smoother and have reduced finger noise.

- Durability: The winding also affects the string’s durability and longevity. Evenly wound strings with consistent tension are less prone to breakage and maintain their tonal qualities over time.

Understanding the winding process and its impact on guitar strings empowers guitarists to make informed choi

ces based on their playing style, instrument, and desired sound. By experimenting with different winding configurations, manufacturers can create strings that cater to the diverse needs of guitarists worldwide.

4. Coating

The coating process is a crucial step in the manufacturing of guitar strings, safeguarding them from the detrimental effects of corrosion and wear. By applying a thin layer of protective material, typically nickel or silver, manufacturers ensure that strings maintain their tonal integrity and longevity.

The coating serves several important functions:

- Corrosion Resistance: The coating acts as a barrier against moisture and other corrosive elements, preventing the string from rusting or tarnishing. This is especially important for strings used in humid environments or by players who frequently sweat.

- Reduced Wear: The coating provides a sacrificial layer that protects the string’s core and winding from abrasion and wear caused by fretting and playing. This extends the string’s lifespan and maintains its optimal tone.

- Improved Tuning Stability: A coated string is less susceptible to intonation issues caused by temperature changes or stretching. The coating helps to maintain the string’s tension and stability, ensuring accurate tuning.

- Enhanced Playability: Coated strings often feel smoother under the fingers, reducing friction and improving playability. This can be particularly beneficial for guitarists with sensitive fingertips or those who play for extended periods.

Understanding the importance of coating in the manufacturing of guitar strings empowers guitarists to make informed choices about the strings they use. Coated strings offer several advantages in terms of durability, tone, and playing feel, making them a valuable consideration for players of all levels.

Table: Coated vs. Uncoated Guitar Strings

| Characteristic | Coated Strings | Uncoated Strings |

|---|---|---|

| Corrosion Resistance | High | Low |

| Wear Resistance | High | Low |

| Tuning Stability | Good | Fair |

| Playability | Smooth | Rough |

| Lifespan | Longer | Shorter |

5. Stretching

Stretching the guitar strings is an essential step in the manufacturing process, directly tied to the overall quality and playability of the final product. It plays a crucial role in ensuring that the strings are in tune and intonated correctly, contributing to the instrument’s overall performance.

- Intonation: Stretching helps to set the intonation of the strings, ensuring that they play in tune at every fret. When a string is stretched, it stretches the core and winding, bringing it to its optimal tension. This ensures that the string produces the correct pitch when played at different positions on the fretboard.

- Tuning Stability: Stretching also improves the string’s tuning stability. By stretching the string, any residual tension or kinks are removed, allowing the string to settle into its proper tuning. This reduces the likelihood of the string going out of tune during playing or under changes in temperature and humidity.

- Tonal Quality: Stretching can also affect the tonal quality of the string. When a string is stretched, it aligns the molecules within the core and winding, resulting in a more uniform structure. This can lead to improved sustain, clarity, and overall tonal consistency.

- Lifespan: Properly stretching the strings can extend their lifespan. By removing any weak points or imperfections, stretching reduces the risk of breakage and premature wear. This can save guitarists money in the long run by reducing the frequency of string changes.

Understanding the importance of stretching in the manufacturing of guitar strings allows guitarists to appreciate the craftsmanship and precision involved in creating high-quality strings. By stretching the strings correctly, manufacturers ensure that guitarists have a reliable and well-tuned instrument that will provide years of enjoyment.

6. Cutting

Cutting the strings to length and packaging them for sale is a crucial final step in the manufacturing process of guitar strings. This seemingly simple task plays a significant role in ensuring the quality and functionality of the strings.

Precision Cutting: The strings are cut to precise lengths to match the scale length of the guitar they are intended for. This ensures that the strings have the correct tension and intonation when installed on the instrument. Inaccurate cutting can lead to tuning issues and intonation problems.

Packaging and Protection: Once cut to length, the strings are packaged in individual envelopes or sealed sets to protect them from moisture, dirt, and corrosion during storage and transportation. Proper packaging also helps to maintain the strings’ coiled shape and prevents tangling.

Practical Significance: The cutting and packaging process ensures that guitarists receive strings that are ready to be installed and used immediately. It also helps to preserve the strings’ quality and lifespan by providing protection against external factors.

Table: Key Insights

| Aspect | Significance |

|---|---|

| Precision Cutting | Ensures correct tension and intonation |

| Packaging | Protects strings from damage and maintains coil shape |

| Quality Control | Provides assurance of consistent string quality |

7. Types

Understanding the diverse types of guitar strings is crucial in the context of “how are guitar strings made” as it highlights the variations and complexities involved in the manufacturing process. Different types of strings cater to specific musical genres, playing styles, and guitar types, and their unique characteristics directly impact the overall sound, feel, and performance of the instrument.

- Materials: Strings can be made from various materials, including steel, nylon, aluminum, and nickel, each offering distinct tonal qualities and playing experiences.

- Construction: Strings can be roundwound, flatwound, or groundwound, with each construction method affecting the string’s texture, brightness, and sustain.

- Coating: Strings can be coated with materials like nickel or silver, which enhances their durability, corrosion resistance, and playing feel.

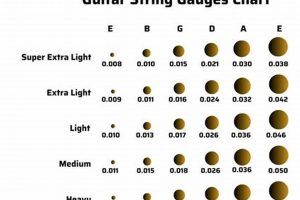

- Tension: Strings come in different tensions, from extra light to heavy, influencing the string’s stiffness, playability, and overall tone.

Recognizing the different t

ypes of guitar strings and their unique characteristics empowers guitarists to make informed decisions when selecting strings that best suit their musical needs and preferences. By understanding the variations in materials, construction, coating, and tension, guitarists can optimize their playing experience and achieve the desired sound and feel from their instrument.

8. Sound

The connection between “Sound: The material and construction of the string impact its sound, from warm and mellow to bright and clear.” and “how are guitar strings made” lies in the direct influence that the materials and construction methods have on the sonic characteristics of the final product. Understanding this relationship is crucial for manufacturers as they seek to create strings that cater to specific musical genres and playing styles.

The material used for the core and winding of the string significantly impacts its sound. Steel strings, for instance, are known for their bright and resonant tone, while nylon strings produce a warmer and mellower sound. The construction method, whether roundwound, flatwound, or groundwound, further shapes the string’s tonal qualities. Roundwound strings have a rougher texture that provides more grip and articulation, while flatwound strings offer a smoother feel and reduced finger noise.

The practical significance of understanding the connection between sound and construction lies in empowering guitarists to make informed choices when selecting strings. By considering the desired sound they want to achieve, guitarists can choose strings that complement their playing style and the genre of music they play. For example, a jazz guitarist may opt for flatwound strings for their smooth, mellow tone, while a rock guitarist might prefer roundwound strings for their brighter, more aggressive sound.

In summary, the exploration of “Sound: The material and construction of the string impact its sound, from warm and mellow to bright and clear.” within the context of “how are guitar strings made” highlights the intricate relationship between materials, construction, and the resulting sound of the string. This understanding is essential for manufacturers and guitarists alike, as it guides the creation and selection of strings that meet specific musical needs and preferences.

Table: Sound Characteristics of Different String Materials and Construction Methods

| Material/Construction | Tonal Characteristics |

|---|---|

| Steel, Roundwound | Bright, resonant, articulate |

| Steel, Flatwound | Warm, mellow, smooth |

| Nylon, Roundwound | Warm, mellow, less bright |

| Nylon, Flatwound | Very warm, mellow, smooth |

9. Tension

Understanding the tension of guitar strings is crucial in the context of “how are guitar strings made” as it directly relates to the string’s playability, feel, and overall performance. Manufacturers carefully consider tension levels to cater to various playing styles and guitar types.

- Tonal Impact: String tension significantly influences the sound and tone of the guitar. Higher tension strings produce a brighter, more resonant sound, while lower tension strings have a warmer, mellower tone.

- Playability: Tension affects the string’s stiffness and elasticity, which in turn impacts its playability. Higher tension strings require more force to fret and bend, while lower tension strings are easier to play and offer a more comfortable feel.

- Intonation and Tuning Stability: String tension plays a role in maintaining proper intonation and tuning stability. Strings with appropriate tension stay in tune better and produce accurate intonation across the fretboard.

- String Longevity: Tension also affects the lifespan of the strings. Higher tension strings are more prone to breakage, while lower tension strings tend to last longer.

Recognizing the importance of tension in guitar string manufacturing empowers guitarists to make informed choices when selecting strings that suit their playing style and the genre of music they play. String tension is an integral part of the equation when designing and producing guitar strings, directly influencing the instrument’s sound, feel, and overall performance.

10. Price

The price of guitar strings is directly tied to the materials used in their construction and the brand that produces them. Understanding this connection is important in the context of “how are guitar strings made” as it sheds light on the factors that influence the cost of these essential guitar components.

- Material Costs: The materials used in guitar string construction, such as steel, nylon, and nickel, vary in cost. Steel strings are generally more affordable than nylon strings, while nickel-plated strings fall somewhere in between. The type of material used for the core and winding of the string can significantly impact the overall price.

- Manufacturing Process: The manufacturing process of guitar strings also influences their price. Roundwound strings, which have a rougher texture due to the way they are wound, are typically more expensive than flatwound strings, which have a smoother feel. The level of craftsmanship and attention to detail involved in the manufacturing process can also contribute to price variations.

- Brand Reputation: The brand that produces the guitar strings also plays a role in determining their price. Well-established brands with a reputation for high-quality products can command a premium price compared to lesser-known brands. Brand loyalty and customer perception can influence the price point of guitar strings.

- String Gauge: The gauge, or thickness, of the strings can also affect their price. Thicker strings, which are typically used for lower tunings, tend to be more expensive than thinner strings. The gauge of the strings influences the amount of material used in their construction, which can impact the overall cost.

Understanding the connection between price, materials, and brand empowers guitarists to make informed decisions when purchasing strings. By considering the factors that influence the cost of guitar strings, players can choose strings that meet their needs and budget, ensuring they get the best value for their money.

11. Maintenance

Understanding the connection between maintenance and the manufacturing process of guitar strings is essential in the context of “how are guitar strings made.” Regular maintenance, including cleaning and restringing, plays a vital role in preserving the quality and performance of guitar strings, extending their lifespan and ensuring optimal playing experience.

- Preserving Tonal Quality: Regular cleaning removes dirt, sweat, and oils that accumulate on the strings, which can dull their sound and affect their

intonation. Cleaning helps maintain the strings’ brightness and clarity, preserving their intended tonal characteristics. - Extending Lifespan: Proper maintenance, including restringing when necessary, helps prolong the life of guitar strings. Worn-out or damaged strings are more prone to breakage, which can disrupt playing and potentially cause damage to the guitar. Regular restringing ensures that the strings are in good condition, reducing the risk of breakage and maintaining optimal playability.

- Maintaining Tuning Stability: Regular maintenance helps maintain the tuning stability of the guitar. Stretched or worn-out strings can lose their tension and go out of tune more easily. Proper restringing and regular tuning ensure that the strings hold their pitch accurately, allowing for precise intonation and consistent performance.

- Preventing Corrosion: Moisture and environmental factors can cause guitar strings to corrode, leading to reduced sound quality and premature breakage. Regular cleaning and the use of corrosion-resistant strings help prevent the buildup of rust and other corrosive elements, preserving the strings’ integrity and extending their lifespan.

By understanding the importance of maintenance in relation to “how are guitar strings made,” guitarists can develop good maintenance habits that will preserve the quality and performance of their guitar strings. Regular cleaning, restringing, and proper storage contribute to the overall longevity and playability of the guitar, ensuring that musicians can enjoy their instrument to its full potential.

FAQs on “How Are Guitar Strings Made”

This section addresses frequently asked questions related to the manufacturing process of guitar strings, providing concise and informative answers to common concerns and misconceptions.

Question 1: What materials are commonly used in guitar string construction?

Guitar strings are primarily made from steel, nylon, aluminum, and nickel. Steel strings offer brightness and clarity, while nylon strings produce a warmer, mellower tone. Aluminum strings combine brightness and warmth, and nickel strings are known for their durability and corrosion resistance.

Question 2: How does the winding process affect the string’s sound and feel?

The winding process involves wrapping a thin metal wire around the string’s core. The tension and pattern of the winding influence the string’s sound and feel. Higher tension produces a brighter, more resonant sound, while lower tension results in a warmer, mellower tone. Roundwound strings have a rougher texture and provide more grip, while flatwound strings are smoother and reduce finger noise.

Question 3: Why is stretching an essential step in guitar string manufacturing?

Stretching helps set the string’s intonation and ensures it stays in tune. It removes any residual tension or kinks, allowing the string to settle into its proper tuning. Stretching also improves the string’s tuning stability and enhances its overall tonal quality.

Question 4: How does the string’s tension impact its playability and sound?

String tension directly affects the string’s playability and sound. Higher tension strings are stiffer and require more force to fret and bend, producing a brighter, more resonant tone. Lower tension strings are easier to play and offer a more comfortable feel, resulting in a warmer, mellower sound.

Question 5: What factors determine the price of guitar strings?

The price of guitar strings primarily depends on the materials used, the manufacturing process, and the brand. Steel strings are generally more affordable than nylon strings, and roundwound strings are typically more expensive than flatwound strings. Well-established brands with a reputation for high-quality products often command a premium price.

Question 6: How can I maintain guitar strings to extend their lifespan and preserve their sound quality?

Regular maintenance, including cleaning and restringing, is crucial for preserving the quality and performance of guitar strings. Cleaning removes dirt, sweat, and oils that can dull their sound and affect intonation. Restringing when necessary helps prevent breakage and ensures optimal playability. Proper storage in a dry environment also contributes to extending the strings’ lifespan.

Understanding these aspects of guitar string manufacturing and maintenance empowers guitarists to make informed decisions about the strings they use and how to care for them. By choosing the right strings for their playing style and instrument, and maintaining them properly, guitarists can optimize their playing experience and enjoy the full potential of their guitars.

Transition to the next article section:

With a comprehensive understanding of how guitar strings are made, let’s delve into the factors that influence their sound and performance, including material selection, construction techniques, and string gauge.

Tips on “How Are Guitar Strings Made”

Understanding the manufacturing process of guitar strings provides valuable insights for guitarists. Here are some practical tips to consider:

Tip 1: Choose the Right Materials

The material of the strings significantly impacts their sound and feel. Steel strings offer brightness and clarity, while nylon strings produce a warmer, mellower tone. Aluminum strings combine brightness and warmth, and nickel strings are known for their durability and corrosion resistance. Consider your playing style and the desired sound when selecting the material.

Tip 2: Pay Attention to the Winding

The winding process influences the string’s tension and tone. Higher tension strings produce a brighter sound, while lower tension strings have a warmer tone. Roundwound strings provide more grip and articulation, while flatwound strings are smoother and reduce finger noise. Experiment with different windings to find the combination that suits your preferences.

Tip 3: Stretch Your Strings Properly

Stretching the strings helps set their intonation and ensures they stay in tune. It removes any residual tension or kinks, allowing the strings to settle into their proper tuning. Stretching also improves the string’s tuning stability and enhances its overall tonal quality.

Tip 4: Consider the String’s Tension

String tension affects the string’s playability and sound. Higher tension strings are stiffer and require more force to fret and bend, producing a brighter, more resonant tone. Lower tension strings are easier to play and offer a more comfortable feel, resulting in a warmer, mellower sound. Choose the tension that suits your playing style and the genre of music you play.

Tip 5: Maintain Your Strings Regularly

Regular maintenance, including cleaning and restringing, is crucial for preserving the quality and performance of guitar strings. Cleaning removes dirt, sweat, and oils that can dull their sound and affect intonation. Restringing when necessary helps prevent breakage and ensures optimal playability. Proper storage in a dry environment also contributes to extending the strings’ lifespan.

By following these tips, guitarists can make informed decisions about the strings they use and how to care for them. Understanding the nuances of guitar string manufacturing empowers guitarists to optimize their playing experience and enjoy the full potential of their guitars.

Transition to the article’s conclusion:

In conclusion, the manufacturing process of guitar strings involves a combination of precision engineering and craftsmanship. By understanding how guitar strings are made, guitarists can appreciate the complexities involved

in creating these essential components and make informed choices that enhance their playing experience.

Conclusion

The exploration of “how are guitar strings made” unveils the intricate processes and dedication that go into crafting these essential components. From the selection of materials to the precise winding and stretching techniques, each step plays a crucial role in shaping the sound, feel, and performance of the strings.

Understanding the nuances of guitar string manufacturing empowers guitarists with the knowledge to make informed choices about the strings they use. By considering factors such as material composition, winding patterns, tension, and maintenance practices, guitarists can optimize their playing experience and achieve their desired sound. Ultimately, the guitar strings serve as a bridge between the guitarist and their instrument, allowing them to express their creativity and connect with audiences through the power of music.