Custom electric guitar builders: The key to your dream guitar

Editor’s Note: Custom electric guitar builders are becoming increasingly popular as guitarists seek to create instruments that are perfectly tailored to their individual needs and preferences. In this guide, we’ll explore the world of custom electric guitar builders, and help you decide if a custom guitar is right for you.

We’ve done the research, dug through the data, and talked to the experts to put together this guide to custom electric guitar builders. We’ll help you understand the key differences between custom and production guitars, and provide you with the information you need to make the right decision for your needs.

Here’s a table summarizing the key differences between custom and production guitars:

| Feature | Custom Guitars | Production Guitars |

|---|---|---|

| Price | More expensive | Less expensive |

| Availability | Limited | Widely available |

| Quality | Typically higher | Varies |

| Customization | Highly customizable | Limited customization |

As you can see, there are several key differences between custom and production guitars. Ultimately, the best way to decide which type of guitar is right for you is to weigh the pros and cons of each option and decide what’s most important to you.

If you’re looking for a truly unique instrument that’s perfectly tailored to your individual needs, then a custom electric guitar may be the right choice for you. However, if you’re on a budget or you’re not sure what you want in a guitar, then a production guitar may be a better option.

No matter which type of guitar you choose, be sure to do your research and find a reputable builder or dealer. This will help you ensure that you’re getting a high-quality instrument that will last for years to come.

1. Experience: How long has the builder been in business? Do they have a good reputation?

When it comes to custom electric guitar builders, experience is everything. A builder with years of experience will have a deep understanding of the craft and will be able to create a guitar that meets your exact specifications. They will also be familiar with the different materials and construction techniques that are available, and will be able to advise you on the best options for your needs.

A good reputation is also essential. This means that the builder has a track record of producing high-quality guitars that meet the expectations of their customers. You can read online reviews to get a sense of what other customers have said about the builder’s work.

Here are a few examples of the benefits of working with an experienced custom electric guitar builder:

- You will get a guitar that is perfectly tailored to your individual needs and preferences.

- You will have peace of mind knowing that your guitar is being built by a skilled and experienced craftsman.

- You will be able to enjoy your guitar for many years to come.

If you are looking for a truly unique and special guitar, then working with a custom electric guitar builder is the best way to go. Just be sure to do your research and find a builder who has the experience and reputation that you are looking for.

Key Insights:

- Experience is one of the most important factors to consider when choosing a custom electric guitar builder.

- A builder with years of experience will have a deep understanding of the craft and will be able to create a guitar that meets your exact specifications.

- A good reputation is also essential, as it means that the builder has a track record of producing high-quality guitars that meet the expectations of their customers.

2. Expertise: What types of guitars does the builder specialize in? Do they have experience building guitars in your desired style?

When choosing a custom electric guitar builder, it is important to consider their expertise. What types of guitars does the builder specialize in? Do they have experience building guitars in your desired style?

If you are looking for a builder who specializes in a particular type of guitar, such as archtop guitars or semi-hollow guitars, then you will want to find a builder who has experience building that type of guitar. A builder who has experience building a variety of different types of guitars will be able to bring a wealth of knowledge and experience to your project.

It is also important to consider the builder’s experience in building guitars in your desired style. If you are looking for a guitar with a vintage vibe, then you will want to find a builder who has experience building vintage-style guitars. A builder who has experience building modern guitars will be able to bring a fresh perspective to your project.

Here are a few examples of the benefits of working with a builder who has expertise in your desired style:

- You will get a guitar that is perfectly tailored to your individual needs and preferences.

- You will have peace of mind knowing that your guitar is being built by a skilled and experienced craftsman.

- You will be able to enjoy your guitar for many years to come.

If you are looking for a truly unique and special guitar, then working with a custom electric guitar builder is the best way to go. Just be sure to do your research and find a builder who has the expertise and experience that you are looking for.

Key Insights:

- When choosing a custom electric guitar builder, it is important to consider their expertise.

- A builder who specializes in a particular type of guitar or style will be able to bring a wealth of knowledge and experience to your project.

- Working with a builder who has expertise in your desired style will help you get a guitar that is perfectly tailored to your individual needs and preferences.

3. Materials: What materials does the builder use? Are they high-quality materials that will produce a great-sounding guitar?

The materials used to build an electric guitar have a significant impact on its sound and playability. Custom electric guitar builders typically use high-quality materials that are known for their excellent acoustic properties. These materials include:

- Woods: The type of wood used for the body and neck of the guitar will affect its tone and sustain. Common woods used for electric guitars include alder, ash, mahogany, and maple.

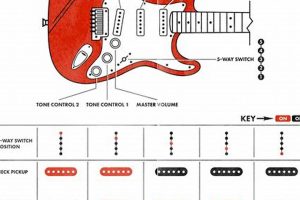

- Pickups: The pickups are responsible for converting the vibrations of the strings into an electrical signal. The type of pickups used will affect the guitar’s sound and output level. Common types of pickups include single-coil pickups, humbucking pickups, and P-90 pickups.

- Electronics: The electronics in an electric guitar include the potentiometers, capacitors, and resistors that control the guitar’s volume, tone, and other functions. High-quality electronics will ensure that the guitar sounds its best and is easy to play.

Custom electric guita

r builders often use a variety of different materials to create unique and innovative guitars. For example, some builders use exotic woods, such as Brazilian rosewood or quilted maple, to create guitars with a distinctive look and sound. Other builders use unconventional materials, such as carbon fiber or aluminum, to create guitars that are lightweight and durable.

Ultimately, the best way to choose the right materials for your custom electric guitar is to work with a builder who understands your needs and preferences. A good builder will be able to help you select the materials that will produce the sound and playability that you are looking for.

Key Insights:

- The materials used to build an electric guitar have a significant impact on its sound and playability.

- Custom electric guitar builders typically use high-quality materials that are known for their excellent acoustic properties.

- The type of wood used for the body and neck of the guitar, the type of pickups used, and the quality of the electronics will all affect the guitar’s sound and playability.

- Working with a builder who understands your needs and preferences is the best way to choose the right materials for your custom electric guitar.

Table: Common Materials Used in Electric Guitar Construction

| Material | Properties | Common Uses |

|---|---|---|

| Alder | Lightweight, resonant, bright tone | Body |

| Ash | Heavy, resonant, warm tone | Body |

| Mahogany | Mid-weight, warm, sustain | Body, neck |

| Maple | Heavy, bright, articulate tone | Body, neck |

| Single-coil pickups | Bright, twangy sound | Fender Stratocaster, Gibson Les Paul |

| Humbucking pickups | Warm, fat sound | Gibson Les Paul, PRS Guitars |

| P-90 pickups | Cross between single-coil and humbucking pickups | Gibson ES-335, Epiphone Casino |

4. Construction: How is the guitar constructed? Is it built to last? Is it well-balanced and comfortable to play?

The construction of a custom electric guitar is one of the most important factors that will affect its sound, playability, and durability. Custom electric guitar builders use a variety of different construction techniques, each with its own advantages and disadvantages.

One of the most important aspects of guitar construction is the choice of wood. The type of wood used for the body, neck, and fingerboard will affect the guitar’s tone, sustain, and weight. Common woods used for electric guitars include alder, ash, mahogany, and maple.

The construction of the guitar’s neck is also important. The neck should be strong and stable, and it should be comfortable to play. The neck joint is also important, as it affects the guitar’s sustain and intonation.

The body of the guitar is also important. The body should be resonant and lightweight, and it should be able to withstand the rigors of playing. The body shape also affects the guitar’s sound and playability.

Custom electric guitar builders use a variety of different construction techniques to create guitars that meet the needs of their customers. Some builders use traditional construction techniques, while others use more modern techniques. Ultimately, the best construction technique for a custom electric guitar is the one that produces a guitar that meets the customer’s needs and preferences.

Here are a few examples of the benefits of working with a custom electric guitar builder who uses high-quality construction techniques:

- You will get a guitar that is built to last.

- You will have peace of mind knowing that your guitar is well-balanced and comfortable to play.

- You will be able to enjoy your guitar for many years to come.

If you are looking for a truly unique and special guitar, then working with a custom electric guitar builder is the best way to go. Just be sure to do your research and find a builder who uses high-quality construction techniques.

Key Insights:

- The construction of a custom electric guitar is one of the most important factors that will affect its sound, playability, and durability.

- Custom electric guitar builders use a variety of different construction techniques, each with its own advantages and disadvantages.

- Working with a custom electric guitar builder who uses high-quality construction techniques is the best way to get a guitar that meets your needs and preferences.

Table: Common Construction Techniques Used by Custom Electric Guitar Builders

| Construction Technique | Advantages | Disadvantages |

|---|---|---|

| Bolt-on neck | Easy to assemble and disassemble, allows for easy neck adjustments | Can be less resonant than other construction techniques |

| Set neck | Stronger and more resonant than bolt-on necks, allows for better sustain | More difficult to assemble and disassemble, neck adjustments are more difficult |

| Neck-through-body | Strongest and most resonant construction technique, allows for the best sustain | Most difficult to assemble and disassemble, neck adjustments are very difficult |

5. Electronics: What electronics does the builder use? Are they high-quality components that will produce a great sound?

The electronics in a custom electric guitar play a vital role in the guitar’s sound and playability. Custom electric guitar builders use a variety of different electronic components, each with its own advantages and disadvantages. The type of pickups, potentiometers, capacitors, and other components used will all affect the guitar’s sound, output level, and tone.High-quality electronic components will produce a better sound and will be more reliable than low-quality components. Custom electric guitar builders typically use high-quality components in their guitars to ensure that the guitars sound their best and are built to last.Here are a few examples of the benefits of using high-quality electronic components in a custom electric guitar:

- The guitar will have a better sound.

- The guitar will be more reliable.

- The guitar will be more versatile.

If you are looking for a custom electric guitar that sounds great and is built to last, then it is important to choose a builder who uses high-quality electronic components.Here is a table that summarizes the key differences between high-quality and low-quality electronic components for custom electric guitars:

| Component | High-Quality | Low-Quality |

|---|---|---|

| Pickups | Made with high-quality materials, such as Alnico magnets and copper wire. | Made with low-quality materials, such as ceramic magnets and steel wire. |

| Potentiometers | Have a smooth, even taper and a long lifespan. | Have a scratchy, uneven taper and a short lifespan. |

| Capacitors | Made with high-quality materials, such as ceramic and film. | Made with low-quality materials, such as plastic and electrolytic. |

By understanding the importance of using high-quality electronic components in a custom electric guitar, you can make an informed decision about the builder you choose. Choosing a builder who uses high-quality components will ensure that you get a guitar that sounds great and is built to last.

6.

Hardware: What hardware does the builder use? Is it durable and reliable?

The hardware on a custom electric guitar is just as important as the wood and electronics. The hardware includes the tuners, bridge, tailpiece, and strap buttons. These components play a vital role in the guitar’s sound, playability, and durability.

Custom electric guitar builders use a variety of different hardware components, each with its own advantages and disadvantages. The type of hardware used will depend on the builder’s preferences and the specific needs of the customer.

Some of the most important factors to consider when choosing hardware for a custom electric guitar include:

- Durability: The hardware should be made from durable materials that can withstand the rigors of playing. This is especially important for components like the tuners and bridge, which are subjected to a lot of wear and tear.

- Reliability: The hardware should be reliable and not prone to failure. This is important for components like the tuners and strap buttons, which can cause major problems if they fail.

- Sound: The hardware can have a significant impact on the guitar’s sound. For example, different types of bridges can produce different tones. It is important to choose hardware that will complement the guitar’s overall sound.

- Playability: The hardware can also affect the guitar’s playability. For example, different types of tuners can make it easier or harder to tune the guitar. It is important to choose hardware that will make the guitar easy and comfortable to play.

By choosing high-quality hardware, you can ensure that your custom electric guitar will sound great, play great, and last for many years to come.

Key Insights:

- The hardware on a custom electric guitar is just as important as the wood and electronics.

- The type of hardware used will depend on the builder’s preferences and the specific needs of the customer.

- Some of the most important factors to consider when choosing hardware for a custom electric guitar include durability, reliability, sound, and playability.

- By choosing high-quality hardware, you can ensure that your custom electric guitar will sound great, play great, and last for many years to come.

Table: Common Hardware Components Used on Custom Electric Guitars

| Component | Function | Importance |

|---|---|---|

| Tuners | Keep the guitar in tune | Essential for accurate intonation and playing in tune |

| Bridge | Supports the strings and transfers their vibrations to the body | Affects the guitar’s tone and sustain |

| Tailpiece | Anchors the strings at the end of the body | Affects the guitar’s intonation and sustain |

| Strap buttons | Attach the guitar strap | Essential for playing the guitar standing up |

7. Finish: What type of finish does the builder use? Is it durable and attractive?

The finish on a custom electric guitar is the final touch that brings the instrument to life. It not only affects the guitar’s appearance but also its durability and playability. Custom electric guitar builders use a variety of different finishes, each with its own advantages and disadvantages.

- Lacquer is a traditional finish that is known for its beauty and durability. It is made from a combination of nitrocellulose and other resins, and it is applied in multiple thin coats. Lacquer finishes are typically glossy, but they can also be sanded to a matte finish. Lacquer is a relatively soft finish, so it is important to be careful not to scratch or damage it.

- Polyurethane is a more modern finish that is known for its durability and resistance to wear and tear. It is made from a combination of polyurethane resin and other chemicals, and it is applied in a single thick coat. Polyurethane finishes are typically glossy, but they can also be sanded to a matte finish. Polyurethane is a harder finish than lacquer, so it is more resistant to scratches and damage.

- Oil finishes are a natural finish that is made from a combination of oils, such as linseed oil or tung oil. Oil finishes are applied by hand, and they are allowed to soak into the wood. Oil finishes are typically matte, and they bring out the natural beauty of the wood. Oil finishes are not as durable as lacquer or polyurethane finishes, but they are easy to repair.

- Wax finishes are a simple finish that is made from a combination of waxes, such as beeswax or carnauba wax. Wax finishes are applied by hand, and they are buffed to a shine. Wax finishes are typically matte, and they protect the wood from moisture and dirt. Wax finishes are not as durable as lacquer or polyurethane finishes, but they are easy to apply and repair.

The type of finish that is best for a custom electric guitar will depend on the builder’s preferences and the specific needs of the customer. However, all of the finishes discussed above can produce a beautiful and durable finish that will protect the guitar for years to come.

8. Price: How much does the builder charge for their guitars? Is it a fair price for the quality of the instrument?

When it comes to custom electric guitar builders, price can be a major factor in the decision-making process. Custom electric guitars can range in price from a few thousand dollars to tens of thousands of dollars, depending on the builder, the materials used, and the level of customization.

- Materials: The type of wood, hardware, and electronics used in a custom electric guitar will all affect the price. Exotic woods, high-quality hardware, and boutique electronics will all add to the cost of the guitar.

- Builder’s reputation: The reputation of the builder will also affect the price of a custom electric guitar. Builders with a good reputation for quality craftsmanship and customer service will typically charge more for their guitars.

- Level of customization: The level of customization that you want for your guitar will also affect the price. A guitar with a simple finish and basic electronics will be less expensive than a guitar with a custom finish, high-end electronics, and intricate inlay work.

Ultimately, the price of a custom electric guitar is a reflection of the quality of the instrument and the level of customization that you desire. If you are looking for a high-quality guitar that is built to your exact specifications, then you should be prepared to pay a fair price for it.

9. Customer service: What kind of customer service does the builder provide? Are they responsive and helpful?

When it comes to custom electric guitar builders, customer service is of utmost importance. A good builder will be responsive to your inquiries, helpful in guiding you through the build process, and supportive after the guitar is complete. Here are a few reasons why customer service is so important:

- Communication is key: Building a custom electric guitar is a collaborative process. The builder needs to be able to communicate with you effectively to ensure that your vision for the guitar is realized.

- Problems can arise: Even the best builders can encounter problems during the build process. A good builder will be upfront with you about any issues that arise and will work with you to find a solution.

- Support after the sale: Once the guitar is complete, you may need ongoing support from the builder. This could include help with setu

p, maintenance, or repairs.

Here are a few things to look for when evaluating the customer service of a custom electric guitar builder:

- Responsiveness: How quickly does the builder respond to your inquiries?

- Helpfulness: Is the builder patient and helpful in answering your questions?

- Support: Does the builder offer ongoing support after the guitar is complete?

By choosing a builder with excellent customer service, you can ensure that you have a positive experience throughout the build process and beyond.

Key Insights:

- Customer service is of utmost importance when choosing a custom electric guitar builder.

- Good customer service includes being responsive, helpful, and supportive.

- By choosing a builder with excellent customer service, you can ensure that you have a positive experience throughout the build process and beyond.

Table: Customer Service Considerations for Custom Electric Guitar Builders

| Factor | Importance |

|---|---|

| Responsiveness | Ensures that your inquiries are addressed promptly. |

| Helpfulness | Provides guidance and assistance throughout the build process. |

| Support | Offers ongoing assistance with setup, maintenance, or repairs. |

Custom Electric Guitar Builders

When considering a custom electric guitar build, several questions and concerns often arise. This FAQ section aims to provide informative answers to guide you in your decision-making process.

Question 1: How do I choose the right builder for my custom guitar?

Choosing the right builder is crucial. Consider their experience, expertise in your desired style, the materials they use, their construction techniques, and their customer service. Research online reviews and reach out to previous clients to gather insights.

Question 2: What are the typical materials used in custom electric guitar builds?

Common woods for the body and neck include alder, ash, mahogany, and maple. Pickups, which convert string vibrations into electrical signals, come in various types such as single-coil, humbucking, and P-90. Electronics, including potentiometers, capacitors, and resistors, influence the guitar’s sound and functionality.

Question 3: How long does it typically take to build a custom electric guitar?

The build time varies depending on the builder’s schedule, the complexity of the design, and the availability of materials. On average, it can take several weeks to several months to complete a custom electric guitar.

Question 4: What is the cost range for a custom electric guitar?

The cost of a custom electric guitar can vary widely. Factors influencing the price include the builder’s reputation, the quality of materials used, the level of customization, and the intricacy of the design. Be prepared to invest accordingly for a high-quality, custom-crafted instrument.

Question 5: How do I maintain my custom electric guitar?

Regular maintenance is essential to preserve your guitar’s performance and longevity. This includes cleaning the body and strings, checking the electronics, adjusting the intonation and action, and restringing as needed. Refer to the builder’s recommendations or consult a qualified guitar technician for specific maintenance advice.

Question 6: What are the benefits of owning a custom electric guitar?

Custom electric guitars offer numerous advantages. They are tailored to your unique preferences in terms of sound, playability, and aesthetics. You can select the exact materials, hardware, and electronics to create an instrument that perfectly complements your musical style and aspirations.

By addressing these common questions, we hope to provide you with a clearer understanding of the process and considerations involved in commissioning a custom electric guitar.

Transition to the next article section: Choosing the right custom electric guitar builder is a significant decision. By carefully evaluating your needs, researching builders, and considering the factors discussed in this FAQ, you can embark on an exciting journey to create your dream guitar.

Tips from Custom Electric Guitar Builders

For those seeking to embark on the journey of crafting their own custom electric guitar, experienced builders offer valuable tips to guide you toward a successful outcome:

Tip 1: Define Your Vision and Goals

Before approaching a builder, take time to envision your dream guitar. Consider its intended sound, playability, and aesthetic appeal. Clearly defining your goals will enable the builder to translate your musical aspirations into reality.

Tip 2: Research and Identify Reputable Builders

Seek recommendations, read online reviews, and examine the portfolios of potential builders. Choose a builder with a proven track record of craftsmanship, attention to detail, and customer satisfaction.

Tip 3: Communicate Effectively

Open communication is crucial throughout the build process. Clearly convey your ideas, preferences, and any specific requirements to the builder. Active listening and regular updates ensure that your vision is accurately realized.

Tip 4: Trust the Builder’s Expertise

While it’s important to articulate your desires, trust the builder’s professional knowledge and experience. They can provide valuable insights on material selection, design choices, and construction techniques that align with your goals.

Tip 5: Be Patient and Respectful

Building a custom electric guitar is an artisanal process that requires time and dedication. Respect the builder’s schedule and understand that unforeseen circumstances may arise. Patience and open communication foster a positive and productive collaboration.

Key Takeaways:

- Clearly define your vision and goals for the guitar.

- Research and select a reputable builder with proven expertise.

- Communicate effectively to ensure your ideas are understood.

- Trust the builder’s knowledge and experience for optimal results.

- Be patient and respectful throughout the build process.

By following these tips, you can increase the likelihood of a successful and rewarding custom electric guitar building experience.

Conclusion

The world of custom electric guitar builders is a vast and ever-evolving landscape. By understanding the key factors to consider when choosing a builder, you can embark on a journey to create an instrument that is uniquely tailored to your musical vision. From materials and construction to electronics and hardware, each decision contributes to the sonic and aesthetic character of your guitar.

Whether you are a seasoned musician or just starting your musical journey, a custom electric guitar can be an investment that brings years of playing enjoyment. Embrace the collaborative process, trust the expertise of your chosen builder, and be prepared to witness the realization of your dream guitar. The end result will be an instrument that not only sounds and plays exceptionally but also holds a special place in your heart as a reflection of your individuality and passion for music.

Youtube Video: